Automation in PIM systems

Product Information MANAGEMENT

Automation – from the Greek for “self-moving” – means that certain tasks are carried out automatically. These tasks are carried out by a machine or system without manual intervention, thus relieving the burden on humans. It only takes on a monitoring function or none at all. In terms of PIM (Product Information Management) systems, automation means using technology to make the collection, management and distribution of product information more efficient. In this blog article, we take a closer look at automation in PIM systems.

Automation not only relieves the burden on people, it also saves time and eliminates errors. It can be implemented both mechanically (use of machines) and software-based (use of software systems). Despite the initially higher effort required to develop the automation process, successful implementation ensures precise and uniform execution of tasks in the long term. In addition, productivity is maximised by the continuous operation of machines and systems because, unlike humans, they do not require sleep or recovery times. Nowadays, automation has even evolved towards intelligence, supported by technologies such as artificial intelligence (AI) and the Internet of Things (IoT), which learn and adapt dynamically.

Brief digression: Automation has been around longer than expected

Automation is not a product of industrialisation. Its origins date back to antiquity, as man has always endeavoured to be efficient in order to make his life easier. In the first century AD, the Greek mathematician and engineer Heron of Alexandria created the first vending machine (a holy water dispenser that dispensed holy water based on the weight of a coin inserted). After that, however, many years had to pass before automation made remarkable progress:

- First industrial revolution in the 18th century: Automation through the use of the steam engine and the mechanisation of production

- Second industrial revolution in the 19th century: Automation through the use of electricity and assembly line production (Henry Ford)

- Third industrial revolution in the 70s: Automation through the use of programmable logic controllers and computers

- Industry 4.0: Automation expanded to include digitalisation and networking

We are currently experiencing the fourth industrial revolution, which is being driven by advancing digitalisation (characterised by key technologies such as the IoT and AI). Today, it is no longer just about automation with machines and computers; instead, physical objects are networked with each other and act intelligently.

Automation in PIM Systems

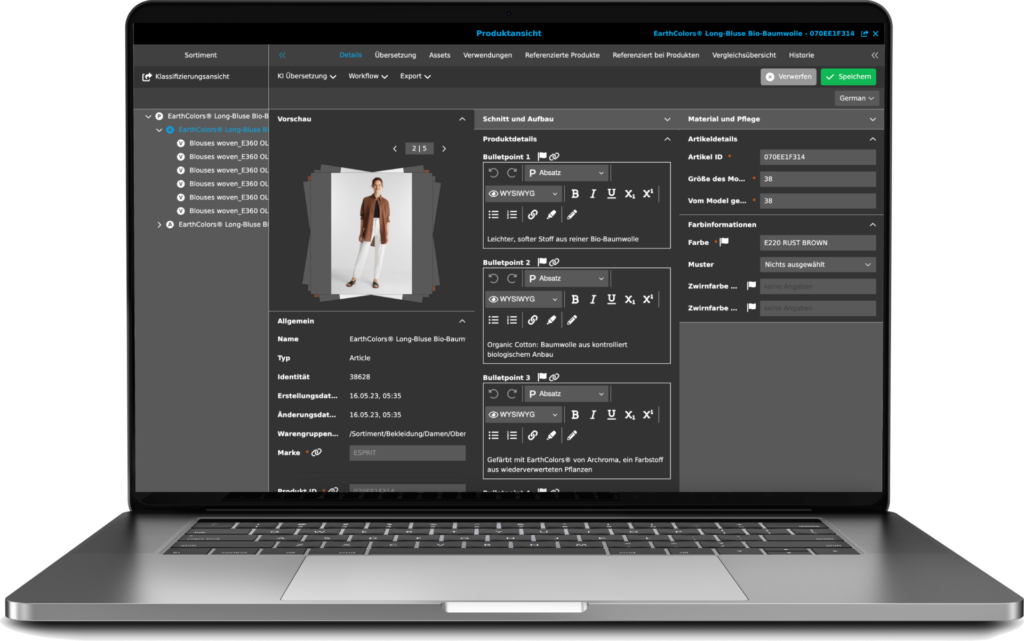

A PIM system is special software that supports the management and communication of product information. Automation involves using technology to control processes and tasks with the help of systems in order to minimise human intervention. Here are some examples of how automation is used in PIM systems:

1. Data Import and Integration (Onboarding)

Product information consists of different data that is available in different systems and must first be merged in order to be effective. These include master data, technical information, visual elements and advertising texts. They can come from an ERP system, a CRM tool or directly from the supplier. With the help of a PIM system and its existing processes and interfaces, all required data is automatically imported and is then available for further processing (data enrichment) in the PIM system. Manual data entry is no longer necessary. The data provided does not have to be checked for completeness either, as exactly the data required for enrichment is imported. Automating data onboarding therefore has many advantages.

2. Data Enrichment

The data enrichment process ensures that the raw data provided is turned into convincing product information. Here, too, automation can greatly reduce the workload. Instead of creating product information by hand, AI can be used. The AI automatically creates product texts suitable for advertising from the existing product attributes (properties and features). Automation can also be used to enrich product data with additional information such as SEO keywords, translations or images.

3. Workflow Management

PIM systems include automated workflows for product release, content review and approval, and other internal processes. This automatically ensures that authorised and correct product information is actually presented in the channels. Digitalised processes also ensure transparency in collaboration, as assigned tasks are clear and have due dates. Queries, delays and errors are eliminated and every work step is easy to follow thanks to automation.

4. Content Syndication

The great advantage of PIM systems lies in automatic syndication. This is used to automatically distribute the finalised product information to e-commerce platforms, retailers, marketplaces and other digital touchpoints. Manual data transfer or uploading of data to the respective channels is no longer necessary. But it is not simply transmitted. During syndication, the PIM system ensures that the product information corresponds to the channel specifications and is therefore displayed correctly at the touchpoints. However, automation in the area of content syndication can also be used to simply try out new channels without having to make large investments.

5. Data Maintenance

Product information is subject to constant updates, whether due to an expansion of the product range or market-related adjustments. Automation can be used to ensure that product information is always consistent and up-to-date, for example by automatically updating changes to product information in all channels. This makes data maintenance child’s play with the support of automation.

6. Quality-Check

Some PIM systems, such as OMN PIM, have a maturity level check. With the maturity check, the PIM system automatically analyses whether the generated product content is literally ready to be presented in the channels. Mature means whether all product data is complete and whether the recorded data is actually correct. The status is displayed using a traffic light system. If the traffic light is green, the data can be transferred to the channels; if not, it must first be revised in the designated fields.

7. Housekeeping

Product data are not static. They are subject to constant change. As a result, data can gradually become “dirty”. Existing data should therefore be regularly cleansed, including in a PIM system. Some PIM systems, such as OMN PIM, have housekeeping automatisms that trigger this cleaning process automatically. This prevents data cleansing from being postponed. The result: data that is always up to date and automatically updated.

8. Reporting and Analysis

A PIM system has automated reporting tools that provide important insights into data quality, usage statistics and more in real time. Thanks to automation, manually generated reports are no longer necessary or reports are provided that were previously unthinkable. Automation therefore also helps greatly with PIM reporting.

Maturity Model in OMN PIM

OMN PIM is our PIM system. One of the amazing features is that it has a maturity model. This is a function that automatically analyses your product data fields for missing values and closes these gaps. This quality analysis helps you to ensure that your product data is both complete and correct before it is sent to your channels. Just one of the examples of automation in our PIM system.

Final thought: Automation in PIM Systems

Product data is subject to constant change. Either new data is added or existing data is supplemented. Keeping pace with the customer can be very labour-intensive and time-consuming. By focussing on automation in the management of product information, for example in data onboarding, text creation and translation or syndication to sales channels, you save an incredible amount of time. The time saved can be put to good use elsewhere. So why try to keep up with the customer when you can be one step ahead? Get to know our PIM system “OMN PIM” today without obligation and benefit from maximum automation in the management of your product information: Request Online Demo >>

Would you like to get to know our OMN PIM?

EXPERIENCE OUR OMN PIM LIVE AND SEE ITS PERFORMANCE FOR YOURSELF!